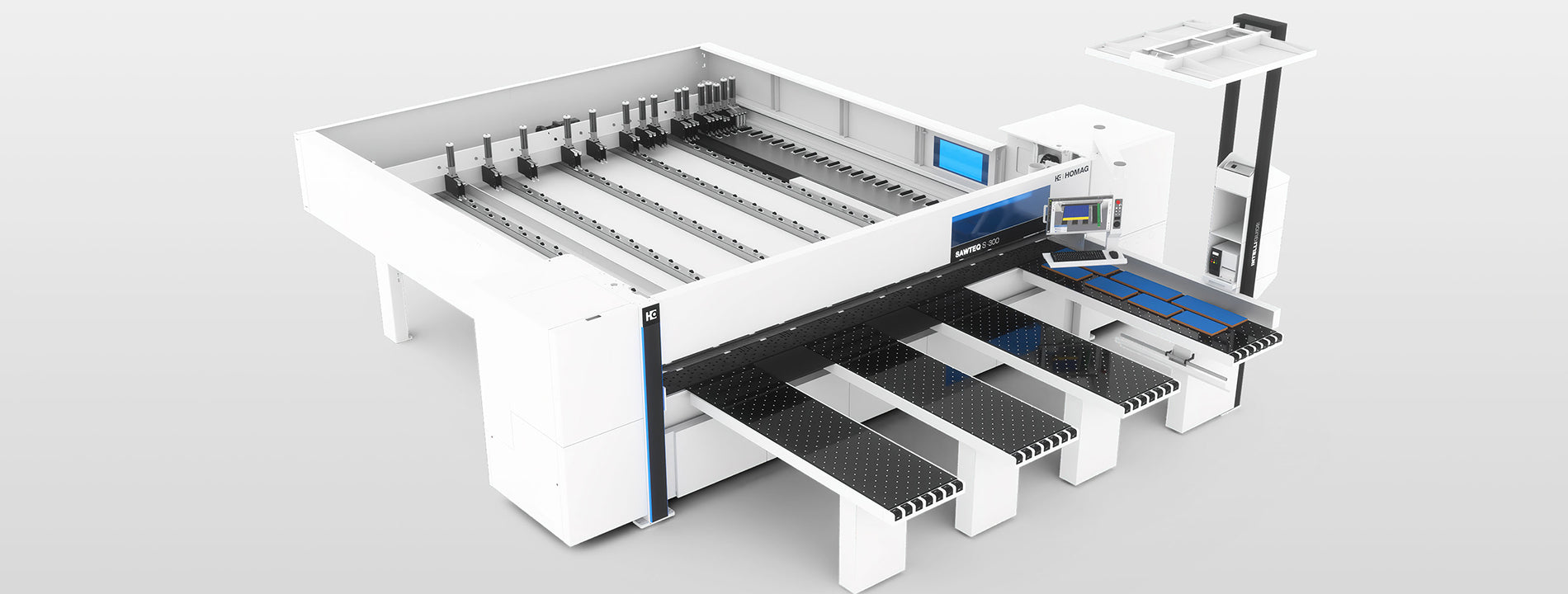

What is a panel sizing machine and how does it work?

The panel sizing machine is an essential tool in many modern woodworking workshops. This specialized industrial equipment is designed to quickly cut panels and other sheet materials into precise shapes and sizes. Panel saws consist of a motorized arm that holds a circular saw blade, as well as a sliding table along which the material moves during the cutting process. The operator programs the machine's settings to accurately control the cut size, then feeds the material onto the sliding table so it can be cut safely and efficiently by the rotating blade. In addition to cutting panels into desired shapes, these machines also allow for features such as notching and plunge cutting, allowing operators to further customize their projects with ease while maintaining consistently high levels of quality and precision.

Benefits of using a panel sizing machine

The panel sizing machine is an invaluable tool for all professional woodworking projects. It provides precision, accuracy and speed that cannot be duplicated by traditional sizing methods. These types of machines ensure a consistent thickness tolerance with every cut made, eliminating waste and creating a high-quality result. The efficiency of a panel sawing machine enables operators to quickly produce finished material in much less time than manual saws can, allowing business owners to increase production capacity and meet tight deadlines. These machines also have the advantage of being safer than manual saws as they have safety guards to protect workers from possible dangers. Overall, the benefits offered by a panel sizing machine make it an excellent investment for any company looking to increase productivity and overall success.

How to choose the right panel sizing machine?

Choosing the right panel sizing machine for your needs can be a difficult task. To ensure you make the right choice, it's important to research the different types of machines available and understand what factors will affect their performance. Different brands and models have a variety of additional features, such as single-axis or multi-axis cutting capabilities, a variety of blade sizes, feed and delivery system configurations, blade speeds and densities, and more. Once you've identified a few panel saws that meet your basic needs, consider functions such as dust collection systems and ease-of-use options that don't impact overall performance but can increase accuracy while minimizing effort. It is also a good practice to read customer reviews to get an idea about user experiences with the saws in question before making your final decision. With the right panel sawing machine at hand, you should be well equipped for all your panel sizing jobs.

How to use a panel sizing machine correctly?

A Panel sizing machine can be a great asset to any business by reducing time spent on tedious cutting tasks. To ensure you get the most out of your panel sizing machine, it is important to take precautions when using and setting up the machine. First, make sure you know all the safety rules; these are usually specified in the Panel sizing machine manual and should always be followed. Secondly, to keep the panel sizing machine in top condition for a longer period of time, ensure that the machine is maintained regularly. Finally, establish specific operating protocols for use and monitoring that everyone who uses the panel sizing machine should know and pay attention to. With these tips, businesses can save time and money while improving the efficiency of their panel sizing operations.

Troubleshooting common problems in panel sizing machines

Panel sizing machines are a tool that many professionals rely on for efficiency and accuracy when creating projects. However, sometimes common problems can arise with their use and can become frustrating if not handled properly. Fixing these problems is the foundation to preventing further damage or even injury. Some of the most common problems with panel sizing machines are electrical malfunctions, inaccurate measurements, faulty blades and motors, as well as other machine errors. In all cases, it is important to stay nearby while troubleshooting to ensure safety and be vigilant in quickly identifying the root cause of any problem. It is also critical to avoid making hasty decisions and double-check all processes before continuing troubleshooting.

A panel sawing machine can be a great addition to your woodworking shop as it offers many advantages over traditional table saws. When choosing a panel saw machine, it's important to consider the panel size you'll be working with most often, as well as your budget and the features that are most important to you. With proper care and regular maintenance, your panel saw machine should provide years of trouble-free service.

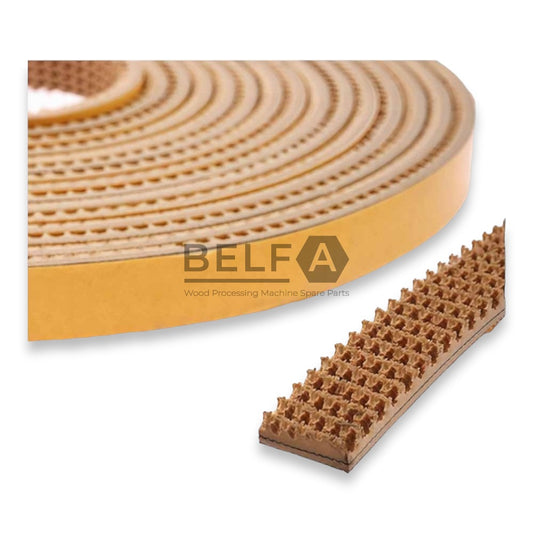

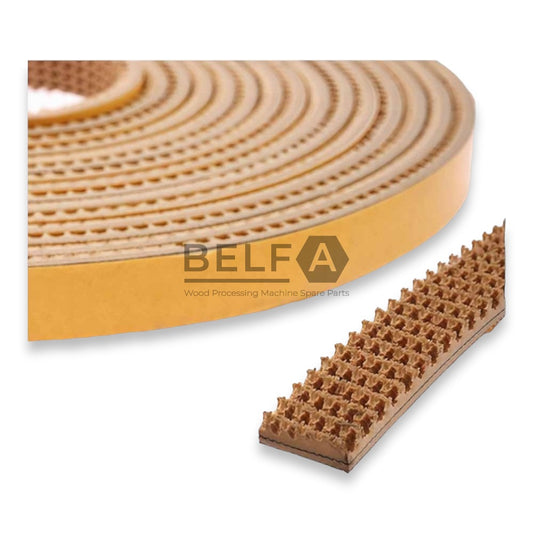

You can find panel sizing parts on this page. Some of our pieces on this page:

Top Pressure Sponge, Gripper, Air Valve, Scraper, Carrier Wheel, Safety Curtain

We have machine parts suitable for every panel sizing machine.

Our panel sizing parts are our own production, you can contact us to purchase.

Sale

Sale Sale

Sale Sale

Sale Sale

Sale Sale

Sale