What is CNC Machine?

A CNC machine is computer numerical control (CNC) equipment designed to automate the cutting and shaping of materials such as metal, wood, plastic, ceramics, and other composites. It typically uses tools such as routers, milling cutters, or drills to shape components with the help of programmable software. The result is an accurate, repeatable and cost-effective production output. CNC machines are used in various industries such as automotive, aerospace, jewelry, industrial machinery and medical equipment manufacturing. They can be used for both prototyping and production work, making them an ideal tool for both small and large businesses.

What are the advantages of CNC machine over traditional machines?

CNC machines or Computer Numerical Control machines are a type of automated machinery equipment used to control the movement and shape of material for use in engineering, manufacturing and other processes. CNC machines offer distinct advantages over traditional tools such as hand-held tools or routers and can achieve precision and repeatability that hand tools cannot achieve. CNC commands can also be programmed by computer so that the same cuts and shapes can be recreated consistently with little change, saving time and labor costs. CNC machines are easy to use, maintain and repair, making more complex manufacturing processes accessible with minimal training. CNC machines provide higher levels of efficiency than traditional manual processes, which require highly skilled labor and increase production time. CNC technology is constantly being improved, making CNC machines increasingly versatile and cost-effective.

How does a CNC machine work and what kind of maintenance does it require?

CNC machines are incredible pieces of machinery that allow accuracy, precision and automation in manufacturing processes. CNC stands for Computer Numerically Controlled and acts on instructions given through a CNC program to create the desired output from a set of materials. CNC machines use tools such as drills, turning tools, and milling tools to cut raw material into the desired finished product. To ensure accuracy and efficient operation of CNC machines, maintenance is required, including regular cleaning of any dust or debris from parts of the machine, as well as checking that all bolts and screws are intact. It is also necessary to periodically check all cables, hoses and other electrical components for wear or damage. Proper CNC machine maintenance helps reduce downtime and improve production rates while reducing the risk of damage or malfunction.

Different types of CNC machines available in the market

With technological advances, CNC machines allow manufacturers and fabricators to create ever more complex and precise parts. They have a variety of different devices available, such as milling machines, lathes, routers and 3D printers. Each type is designed for a specific purpose, such as milling complex shapes, cutting complex curves or creating contoured surfaces, making it possible to tackle almost any project. CNC mills have three main axes, X, Y and Z, to create the desired shape and size by moving the cutting tool along each plane. In addition to speeding up production time, CNC machines can also accurately reduce the costs associated with making parts. With improved accuracy over manual machines, multiple tools to measure progress, and safety checks for operators built into each machine. Whatever your industry or project outcome, you're sure to find a CNC machine that can get the job done.

How do you choose the right CNC machine?

Choosing the right CNC machine can be a difficult task. It is important to thoroughly research different options from qualified sellers before committing to purchase. Consider the type of material you need to work with and the finish quality you want. Also consider how much space you have for the project and whether ease of use is a priority over overall speed. Researching user reviews can provide useful information from other machine owners. You should also consider your budget when weighing your choices to avoid pulling resources away from other areas of your business plan.

Basics of using CNC machine

Operating a CNC machine is an important task for those working in the manufacturing industry as it is vital to providing high standard parts and components. There are several steps to using these machines correctly and efficiently, from adjusting the machine's controls by entering the correct data such as material or part size, speed and feed rate, to making test cuts to ensure accuracy. It is crucial that operators are familiar with safety protocols, such as using face protection, checking for loose clothing and other obstructions that may interfere with moving parts of the machine. Additionally, understanding how to select cutting tools designed for the application, how to operate auxiliary functions such as coolant systems, and proper shutdown procedures round out the basics of operating a CNC machine.

Tips to get the most out of your CNC machine

Investing in a CNC machine is a great way to save time and increase the efficiency of your workflow. With proper maintenance and operation, you can achieve maximum productivity from your CNC machine. To get the most out of your investment, start by understanding what types of dynamics work best for your particular application. Consider engine types and tooling selection so you can improve performance and reduce costs associated with wear and tear components. Make sure you focus on causes rather than symptoms so you understand why certain problems are occurring and address them before they become too costly. Also check regularly for blown fuses or missing wires, as these problems can lead to significant delays if not detected in time. Taking all these factors into consideration will help you maximize the versatility of your CNC machine efficiently.

CNC machines offer a number of advantages over traditional manufacturing methods, such as greater accuracy, speed and efficiency. There are a variety of CNC machines on the market to suit many different needs. When choosing a CNC machine, it is important to consider factors such as size, power and price. With proper maintenance and repair, your CNC machine can provide years of reliable service. By following these tips you can get the most out of your machine and maximize its potential.

CNC Spare Parts and Accessories

CNC Spare Parts are spare parts that need to be constantly maintained and renewed in the CNC machine. CNC Machine enables precision, high speed and powerful mass production. It allows you to quickly produce the part you want to produce by cutting, drilling and sawing different materials such as metal, plastic, wood, glass, foam and composite from an empty block with knives.

Different types of CNC spare parts and their uses. There are various other parts that can be classified into different categories such as bearings, belts, chains, gears and more. Each part has a unique function and is necessary for the overall operation of the CNC machine. Knowing what these parts are and what they do can help you troubleshoot problems that may arise with your CNC machine.

CNC machines are complex pieces of equipment that need a variety of different parts to function properly. Each of these parts has a specific purpose and is necessary for the overall operation of the machine.

You can separate CNC machine spare parts into mechanical and electronic. Belfa Machinery currently only sells CNC mechanical parts.

CNCs consist of many different mechanical spare parts. Active spare parts begin to wear out with use, reducing the performance of the machine and slowing down production. Obtaining these spare parts from the original brand is both expensive and time-consuming. At this point, as Belfa Machinery, we become the solution partner of our customers with fast and cheap CNC parts supply.

Quality CNC Spare Parts extend the life of your machine, increase your production capacity, and enable you to carry out your operations with precision.

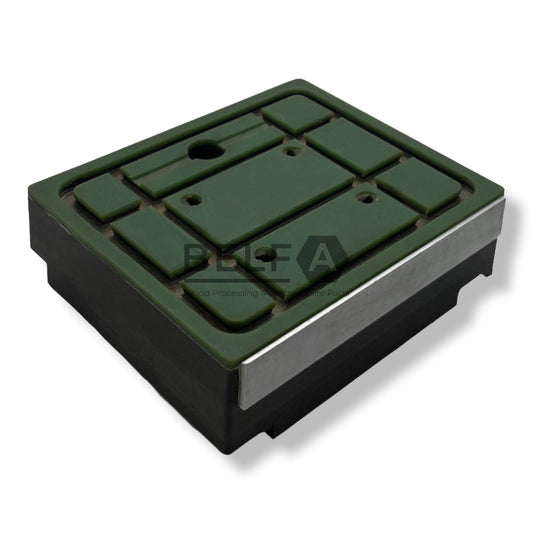

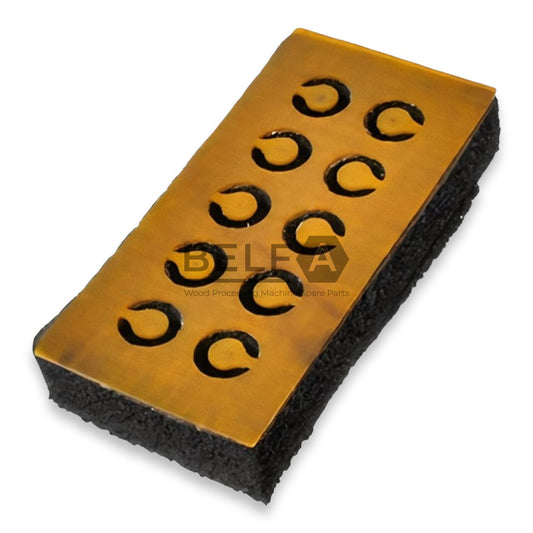

Vacuum Accessories for CNC Mechanical parts and Wood CNC Machining Center Part Fixer

Vacuum your part securely with

our vacuum blocks for part fixing in Wood CNC Machining centres, leaving no room for millimeter error during the process. We have vacuum blocks suitable for all processing centers. If you cannot see your own measurements, you can contact us immediately via WhatsApp,

phone or

e-mail .

Payment and Shipping

Spare Parts are delivered to Domestic Cargo on the same day, ensuring fast and safe shipping.