Edge Banding Machine Spare Parts

-

Homag Top Strap Wheel

Regular price 350.00TLRegular priceUnit price / per -

Homag Radius PVC Grazer

Regular price 275.00TLRegular priceUnit price / per -

Cotton Airway Buffing Wheel

Regular price From 475.00TLRegular priceUnit price / per -

Glue Level Sensor

Regular price From 3,850.00TLRegular priceUnit price / per -

Beam Wheel Side Rollers

Regular price From 55.00TLRegular priceUnit price / per0.00TLSale price From 55.00TL -

Gummed Wheel

Regular price From 425.00TLRegular priceUnit price / per0.00TLSale price From 425.00TL -

Geared Round Coupling

Regular price 450.00TLRegular priceUnit price / per -

Chain Pads

Regular price From 145.00TLRegular priceUnit price / per -

Tape Feeding Roller

Regular price From 650.00TLRegular priceUnit price / per -

Rubber Pressure Wheel

Regular price From 165.00TLRegular priceUnit price / per

belfa machine

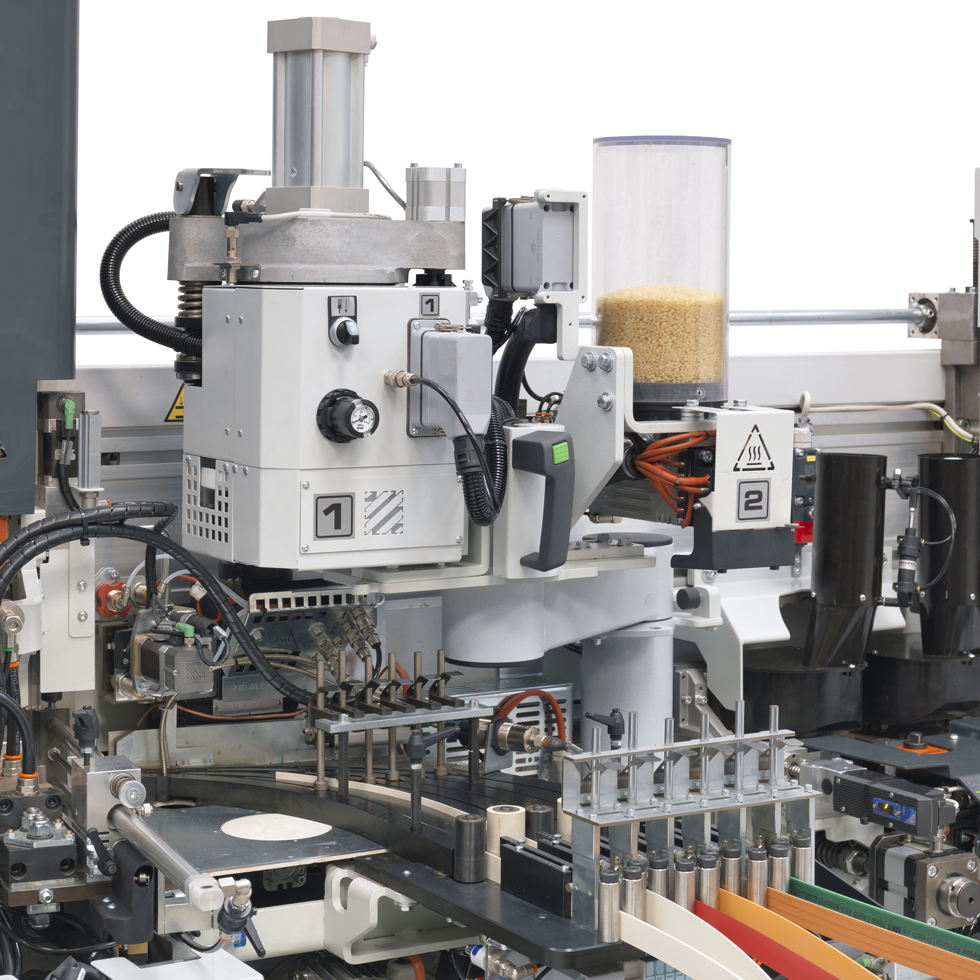

Edge Banding Machine Spare Parts

Belfa Machinery meets all kinds of spare parts needs of your edge banding machine. From the smallest component to the most critical parts, we offer quality and compatibility guarantee. We are here to increase the performance and productivity of your machine with our fast delivery and customer-oriented service approach. Keep your edge banding machine working at its highest level with Belfa Machinery.

Collection: Edge Banding Machine Spare Parts

What is an edge banding machine and what does it do?

Edge banding machines are an essential tool for woodworking projects as they provide a smooth edge to wood products. An edge banding machine applies a thin strip of veneer, PVC, or other edge material to the edge of furniture pieces such as laminate countertops, cabinets, and particleboard panels. The edge strip is first softened by contact with hot glue, then firmly attached to the edge with pressure rollers, which cut the edge to size during the process. Edge banding machines ensure your wood projects have smooth, finished edges and typically feature an adhesive system, a cutting head, and grooving and milling capabilities. From small-scale home renovations to commercial furniture production, edge banding machines are invaluable tools in creating quality project results. Simply put, edge banding machine solves the problem of ugly and raw edges on furniture. It also reduces the effects of liquid spills, atmospheric humidity, and humidity in general. This helps prevent the wood panels on your furniture from being destroyed.Where is Edgebanding Used?

Edge banding machine is used to quickly band the edges of materials such as plywood, MDF or chipboard. It is especially used in the door and furniture sectors.What are Edge Banding Parts?

Edge banding machine parts are very diverse, apart from mechanical parts such as pressure wheel, head-end cutting wheel or bottom pallet shoe, there are also fixed parts such as glue pot. In addition to too many mechanical parts, it also brings a lot of wear, and at this point Belfa Machinery's spare parts enable our customers to obtain spare parts cheaply and quickly and continue their production without interrupting their production. Edge banding, especially in commercial settings, is done using an edge banding machine that applies a hot melt adhesive to the edge of the board. This hot melt adhesive is a type of thermoplastic adhesive that holds the edge strips firmly in place. An edge banding machine is a machine used to automatically create decorative edges on panels and sheets. The machine cuts the edge of the wood and then uses glue to attach colored edging strips or other materials. It can also be used for decorative purposes, such as making patterns with cut pieces of wood or different types of metal. An edge banding machine is useful when working in batches and/or repeating multiple patterns on a piece of furniture. It is mainly used to strengthen the edges of plywood panels, chipboards or MDF, making them more durable and less susceptible to damage. Our edge banding parts are our own production, you can pay by credit card or EFT / Money Order. Shipments are provided within the day by Yurtiçi Kargo.How Does an Edge Banding Machine Work?

Most edge banding machines work by feeding an edge stripper through a machine until it is tight against the treated particleboard. A roller or hot air gun then applies heat to activate the adhesive and hold the strip in place. A clamp then presses and holds the taping firmly against the edge of the board as it passes through a roller press for a few seconds to ensure there is sufficient glue on all parts of the taping material. A second roller or hot air gun applies more heat, melting any remaining glue so you can easily cut off the excess taping material and the board is ready to use.There are at least four other methods for applying edgebanding.

- hot air/laser

- Ironing

- laser edge

- edge banding tape